The technique for making thin, flat window glass was perfected in Normandy, France, in the 14th century. Known as crown glass, each piece was blown by a craftsman. An accomplished glass-bowler could make only about a dozen windows in a day, making medieval window glass an expensive luxury.

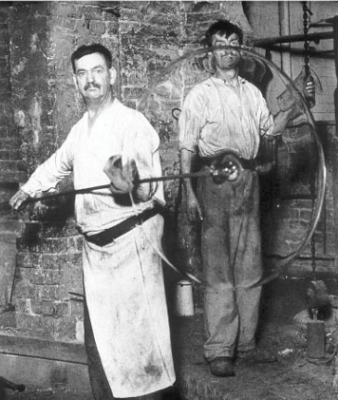

For each pane, the molten glass is blown into a large bubble using a blowpipe. The bubble is then flattened and attached to the end of an iron rod, called a punty, which is rotated as possible by the craftsman.

The flattened bubble of glass fans out to form a circle 3ft to 6ft (1m to 2m) wide, depending on the size of the original bubble and the skill and strength of the craftsman.

The round, flat glass sheets were then cut for use as small window panes, particularly in churches. The ‘bullseye’ at the centre of the disc was the least transparent section, but because glass was so expensive, it would have been used anyway.

Picture Credit : Google