Additive manufacturing, more commonly identified as 3D printing, allows for the fabrication of complex parts from functional or biological materials. As objects are constructed one line or one layer at a time, conventional 3D printing can be a slow process.

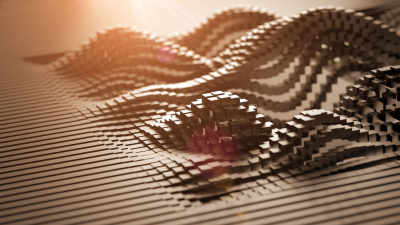

Scientists from the Max Planck Institute for Medical Research and the Heidelberg University have demonstrated a new technology to form a 3D object from smaller building blocks in a single step. They utilise the concept of multiple acoustic holograms to generate pressure fields.

Sound exerts force

If you've ever been near a powerful loudspeaker, you would be aware that sound waves exert forces on matter. When high-frequency ultrasound that is inaudible to the human car is used, the wavelengths can be pushed into the microscopic realm. This would allow researchers to manipulate building blocks that are incredibly small, including biological cells.

This research group had previously shown how to form ultrasound using acoustic holograms, which are 30 printed plates made to encode a specific sound field. The scientists had devised a fabrication concept to use these sound fields to assemble materials in 2D patterns.

Holds promise

For this research, the team expanded the concept further by capturing particles and cells freely floating in water and assembling them into 3D shapes. Additionally, the new method works with materials such as glass, hydrogel beads, and biological cells.

Ultrasound affords the advantage that it is gentle for using biological cells and that it can travel deep into tissue. Hence, it can be used to remotely manipulate cells without harm. Scientists believe that their technology of creating 3D objects with sounds holds promise as it can provide a platform for the formation of tissues and cell cultures.

Picture Credit : Google