What are the types of engineers?

Our world is full of mechanics that help us use things, go places, and communicate. Engineers help make all this possible. Here are just a few types of engineers and what they do.

Architectural engineers

Architectural engineers develop better ways of building homes and other buildings. They also find ways to make buildings taller. They apply the latest scientific knowledge and technologies to the design of buildings. Architectural engineering as a relatively new licensed profession emerged in the 20th century as a result of the rapid technological developments.

Chemical engineers

Chemical engineers design ways to end pollution. They create drugs to fight cancer and other illnesses, too. Chemical engineers work mostly in offices or laboratories. They may spend time at industrial plants, refineries, and other locations, where they monitor or direct operations or solve onsite problems. Nearly all chemical engineers work full time.

Civil engineering

Civil engineering is the oldest kind of engineering. Civil engineers design bridges, subways, roads, dams, and canals. Civil engineering is traditionally broken into a number of sub-disciplines. It is considered the second-oldest engineering discipline after military engineering, and it is defined to distinguish non-military engineering from military engineering.

Electrical engineers

Electrical engineers design equipment that produces electric power and sends it to our homes. They also design computer circuits and robots. Electrical engineers work in a very wide range of industries and the skills required are likewise variable. These range from circuit theory to the management skills of a project manager. The tools and equipment that an individual engineer may need are similarly variable, ranging from a simple voltmeter to sophisticated design and manufacturing software

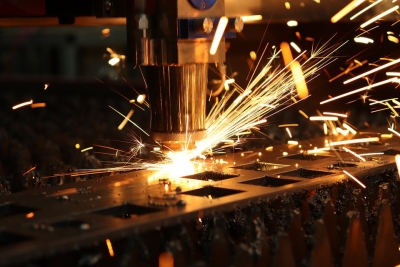

Materials engineers

Materials engineers work out how to make the produces we use better. They develop new materials for making anything from hand tools to huge trains. They also find new ways to use the materials we already have.

Mechanical engineers

Mechanical engineers design new machines. Some mechanical engineers invent better ways of heating and cooling homes and buildings. The mechanical engineering field requires an understanding of core areas including mechanics, dynamics, thermodynamics, materials science, structural analysis, and electricity.

In many ways, engineers are helping to design the future.

Picture Credit : Google